Ucrete,

the World’s Toughest

Floor Since 1969

Ucrete industrial flooring is a family of heavy duty resin systems widely used in Food&Beverage, Chemicals and Pharmaceutical industries.

Why choose Ucrete industrial flooring? Hover over the icons to find out Ucrete’s unique benefits!

Hygiene

No food contamination.

Ucrete is accredited for use in food facilities operating HACCP quality systems and also carries the Eurofins Indoor Air Comfort Gold Label for low emissions.

- Impervious and non-absorbent

- Anti-microbial without the need for biocidal additives

- Washable and non-toxic

- Non-solvent and non-tainting from the end of mixing

- Approved to EN 4120, as certified by Campden BRI

Chemical resistance

No corrosion.

Ucrete is resistant to a wide range of aggressive chemicals used in many industries. It resists the organic and inorganic acids and alklis encountered in the food industry and used for regular cleaninng and sterilization procedures.

Thermal resistance

No softening, erosion or delamination.

Ucrete is used over a wide temperature range, from -40 °C up to +130 °C, and some specifications are able to withstand also occasional spillages up to +150 °C. A 9 mm thick Ucrete floor will withstand regular and routine discharges of boiling water.

Impact resistance

No cracking or debonding.

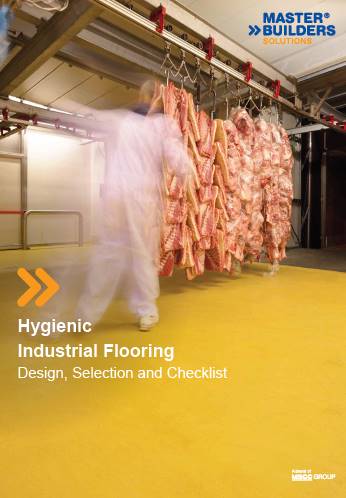

Ucrete is extremely tough. No damage will occur to the floor surface even under the heaviest impacts such as the dropping of meat hooks in an abattoir, steel kegs falling off a line in a brewery or the dropping of tools and access covers during maintenance.

Slip resistance

Safe work environment.

Ucrete is available in a range of surface profiles from smooth to highly textured floors, available matt or gloss and as cleanable as stainless steel, to achieve the right degree of slip resistance tailored to your needs. A perfectly safe working environment for your employees is possible with an holistic approach combining engineering solutions, correct working and cleaning procedures as well as good footwear and floor.

Fast return to service

Money saving.

Ucrete is non tainting from the end of mixing so can be used for installations within a working factory causing no production downtime. Fast curing specifications are available that allow the floor to be put back into service after 5 hours, even at 10 oC allowing overnight installation, minimising operational downtime. Not just a patch repair but a fully functional Ucrete floor that will provide many years of maintenance free service.

Ucrete is dense and impervious, it is the ideal flooring solution where the highest hygienic standards are required and for the toughest industrial environments. We challenged the resistance of this floor against extreme temperatures, corrosive acids and the most aggressive impacts. No cracking, debonding, delamination nor softening of any kind occurred. Have a look at this video to check out how tough Ucrete is.

Welcome to the Ucrete destruction challenge!

Hygienic floors - Preparation, choice and checklist

Production processes take place on the floor. If the floor provides a safe and attractive environment for the workers and is hygienic and easy to clean, production efficiency will be high. In fact, good floor selection, design and construction minimize accidents, hygiene risks and lost production. The aim of this white paper is to identify the best practice for floor design and specification to achieve a long lasting functional flooring solution with particular regard to the food and beverage industry.